|

N3200G/G+ multifunctional portable 40KHz ultrasonic leak detector

다기능 휴대용 초음파 누출 감지기 N3200G/N3200G+

응용 분야

석유 화학, 가스 전송, 전력 전자, 국방군,

선박 항공, 기계 제조, 자동차 제조,

교통, 금속 제련, 의학 및 건강, 식품 및

음료, 광산 시멘트, 유리 제조, 제지 인쇄,

지하철 선풍기, 대형 에어컨, 청소 시스템, 수처리 및 기타 분야.

화학 플랜트 가스 누출 감지 및 검사

발전소의 공랭식 섬의 진공 누출 감지

공기 분리 장비 누출 감지

천연 주유소, 파이프 라인 및 밸브의 누출 감지

전송선의 방전 감지

전기 장비 방전 감지

GIS / GCB 변전소 감지

N3200G/G+ multifunctional portable 40KHz ultrasonic leak detector

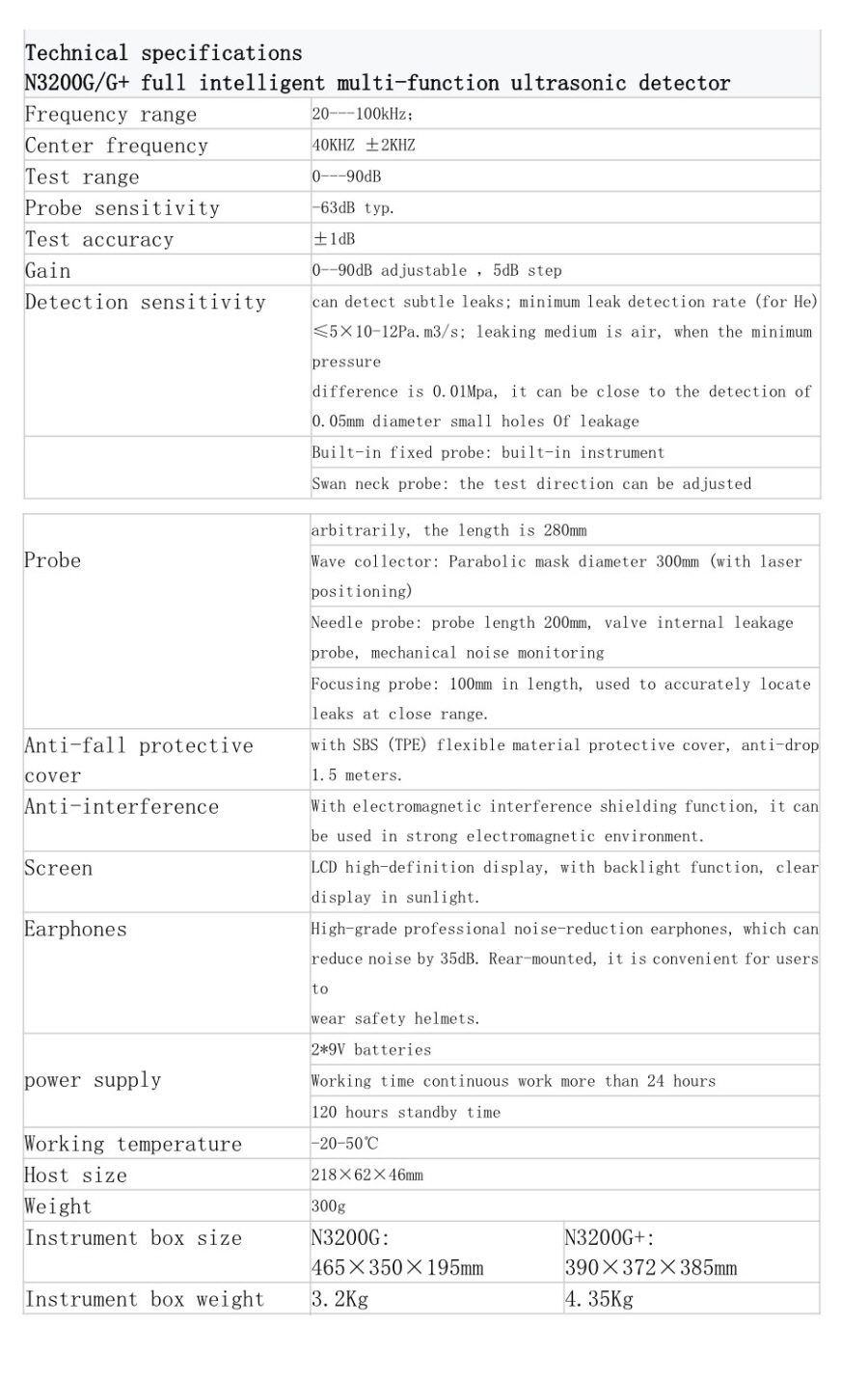

N3200G/G+ is an all-intelligent ultrasonic detector. The instrument can detect tiny gas leaks and tiny electrical discharges by capturing, amplifying, detecting, and decoding ultrasonic waves, and turning the leakage and discharge phenomena into what the human ear hears. The sound signal also displays the leakage and discharge intensity values on the instrument screen.

* The core sensors and components of the instrument are imported from abroad, which ensures the reliability; adapt to the harsh working environment;

* Using electromagnetic compatibility technology and unique noise shielding technology, anti-interference, anti-electromagnetic, anti-noise.

* Adapt to the field of high-voltage power electromagnetic radiation.

* Adapt to the detection of strong noise environment on the industrial site, completely shield the noise, and only collect the leakage/discharge ultrasonic signals.

* The instrument is hand-held and portable, and can be operated with one hand, with light weight, easy operation, sensitive reaction and accurate test.

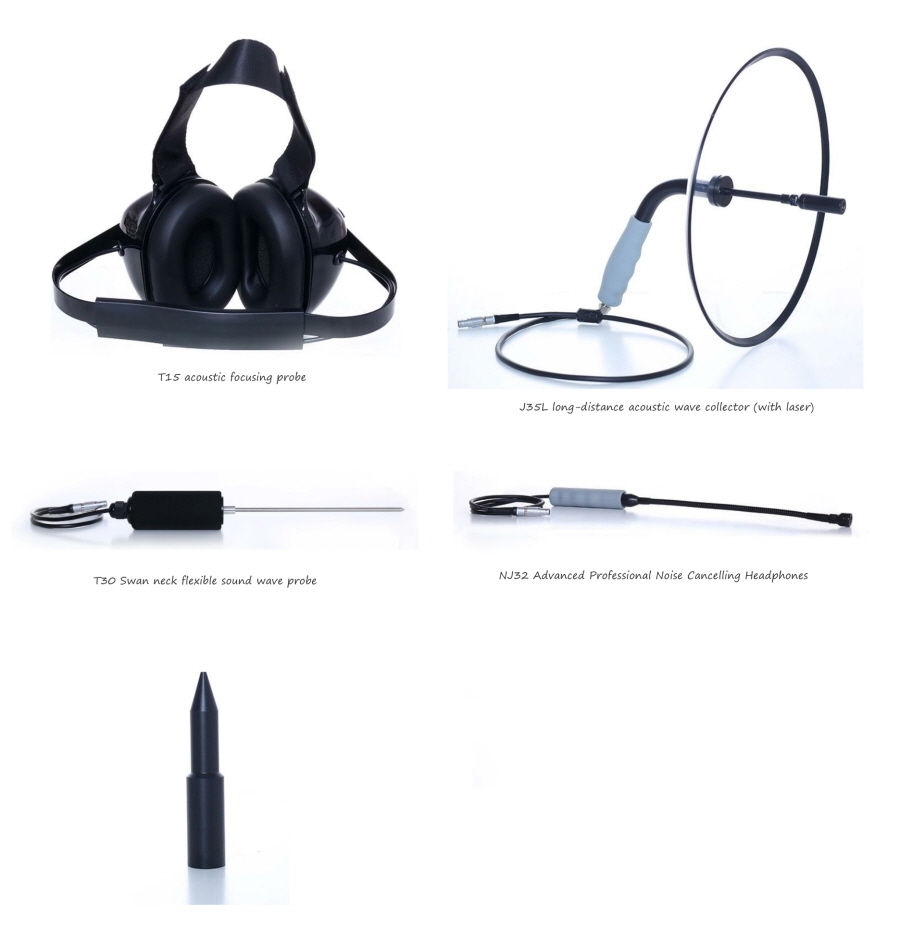

* Multifunctional ultrasonic leak detector, equipped with a variety of detection technologies and sensors, to meet the needs of on-site testing, all leaks have nothing to escape.

* Through the real-time test value on the display screen, the leakage and discharge degree can be visually displayed and the severity can be determined.

Product performance characteristics

* Anti-interference Effectively shield electromagnetic interference and non-leakage noise; it can accurately locate leaks and faults in noisy and complex scenes.

* Fully intelligent one-key test, easy to learn and understand, and can quickly master the use method.

* Sensitive The leaking medium is air. When the pressure is 0.01Mpa, it can detect the leakage of 0.05mm diameter small hole close to it.

* Adjustable gain The gain can be adjusted to the best test sensitivity according to the site leakage source and environmental interference, and all small leaks can be captured.

* Quickly detect leaks by scanning.

* Precision The laser sight and precise focus positioning probe can accurately locate the leak point, which is convenient for plugging.

* Multi-function is equipped with contact probe probe, which can detect the internal leakage of the valve and monitor the noise of mechanical failure.

* Remote can be remotely detected by using a remote wave collector; according to the difference between positive and negative pressure systems, the longest detection distance is up to 50 meters.

* Widely suitable for detecting any pressure gas leak, vacuum leak, electrical discharge, and tank seal detection.

* Convenient handheld, light weight, easy to operate; convenient for daily inspection and use.

* Environment Working temperature -20℃--50℃, dustproof and high temperature resistant.

* Headphones: Advanced professional noise-reducing headphones, which can reduce noise by 35dB. Supports wearing a helmet, suitable for strong noise environment in the factory.

* Anti-fall protection With SBS (TPE) material protective sleeve, anti-drop 1.5 meters.

* Ultra-long standby can work continuously for more than 24 hours (continuous leakage sourc

e). Standby time is greater than 120 hours.

Applications

Application fields

Petrochemical, gas transmission, power electronics, defense military, ship aviation, machinery manufacturing, automobile manufacturing,

transportation, metal smelting, medicine and health, food and beverage, mining cement, glass manufacturing, papermaking printing, subway fans, large air conditioners, cleaning Systems, water treatment and other fields. Chemical plant gas leak detection and inspection Vacuum leak detection of air-cooled islands in power plants Air separation equipment leak detection Leakage detection of natural gas stations, pipelines and valves Discharge detection of transmission lines Electrical equipment discharge detection GIS/GCB substation detection Engineering quality inspection, eliminating the need to pressurize and maintain pressure, shorten engineering time, and quickly detect leaks Application ranges

* Leakage of air separation system * Gas leakage of pressure vessels and pipelines * Leakage of compressed air unit and pipeline * Leakage of vacuum container and equipment * Air-cooled island leakage * Tightness test * Natural gas stations and pipelines

* Partial discharge of electrical equipment * Partial discharge of transmission lines * Inner leakage detection of valve * Steam trap leakage * Motor mechanical failure * Leakage in clean machine room and laboratory * Suitable for any pressure gas leakage

FAQ

Q1: What kind of gas leak will be detected by ultrasound? Generally speaking,

any gas, including air, will produce an ultrasonic leak signal through the leak

point. The specific and reasonable design of N3200G/G+ is different from

professional gas sensor detectors. It is designed to detect gas sensors limited to

special gases (ie, helium). Because it detects ultrasonic signals, the N3200G/G+

can detect ultrasonic signals generated by any kind of gas leakage. Because of its

wide range of uses, the N3200G/G+ can be used for various leak inspections,

such as: pneumatic system inspection, high-voltage cables, power

telecommunications, air brake systems for train cars, air brake systems for

trucks and buses, Storage tank, pipeline, shell. It is easy to detect the

pressurization of the casing and piping. Vacuum systems, exhaust gas from

turbines, vacuum chambers, material handling systems, condensers, oxygen

systems, etc. can be easily detected by detecting the long-lived ultrasonic signals

of leaks.

Q2: How to conduct ultrasonic testing on partial discharge of power

equipment? When the current escapes from the high-voltage line or jumps

through the gap at the connection site. The air molecules around it are disturbed

to generate an ultrasonic signal, so when the user uses an ultrasonic detector to

detect, this signal can be detected. Most of the time, the user usually monitors

a series of popping sounds or "fried" In other cases, you will hear a "buzzing" noisy

sound. Typical applications include: insulators, wires, switchgears, high-voltage

busbars, relays, circuit breakers, contactors, junction boxes, substations,

insulators, transformers and high-voltage insulation bushings, etc. Ultrasonic

testing is often used for closed switchgear, because ultrasonic emissions can be

found by scanning the surrounding door joints and vents, such as switches that

arc, discharge, and corona. It may be found that there is a serious failure,

without having to consider using infrared light scanning offline. However, we

recommend that for closed switchgear. Both of these detection methods can be

used. If long-distance electrical lines are inspected from the ground, but the

signal is not very strong, an ultrasonic wave collector (a parabolic antenna

reflector) can be used to double the detection distance of the system and provide

accurate detection for the N3200G/G+.

Q3: What else can we do? We can

customize and develop products according to user requirements, such as:

establishing a data model library, automatically determining the actual

leakage/discharge of user equipment, simultaneous acquisition of multi-channel

ultrasonic signals, online ultrasonic leakage/discharge online monitoring, and

robot/unmanned The aircraft is equipped with ultrasonic online monitoring,

infrared thermal imaging/ultrasonic integrated acquisition and analysis, etc. Users and distributors are welcome to call for consultation!

|